This is the second post in our new blog series, which provides crucial ERP evaluation and implementation considerations for senior management personnel.

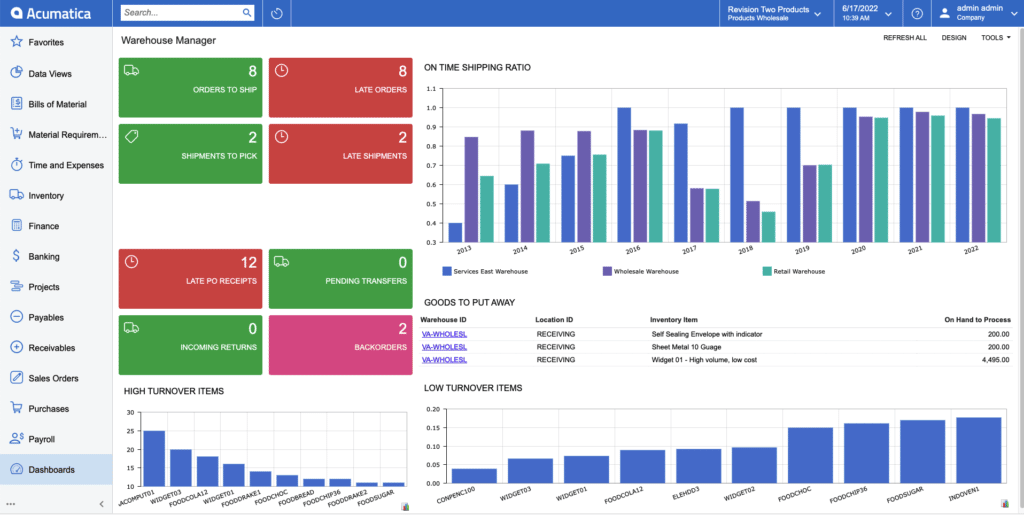

Our goal for this blog is to provide a view into ERP for Warehouse Managers and stakeholders in purchasing and operations.

If you are a CEO or CFO, please click here to read our previous post.

Boosting Profitability and Efficiency

With longer lead times, increased demand, high employee turnover, and unique requirements specific to your business, it is vital to consider a flexible platform that can support your goals of maintaining a lower carrying cost alongside a higher fulfillment rate.

As you search for a new ERP, systems that are based on live data with flexible reporting options that complement the operational functionality needed to provide accurate replenishment suggestions, automate your purchasing process, maintain accurate inventory, and optimize your order fulfillment are key to boosting your team’s efficiency and meeting your business goals.

Replenishment: Lower Carrying Cost

It can be difficult to maintain optimal inventory levels that allow you to fulfill all your orders on time, without disrupting your cash flow and warehouse space with overstock. An ERP with integrated modules for inventory, order management, and manufacturing (if needed) can provide you with replenishment suggestions that are generated based on your min/max settings, vendor lead times, safety stock parameters, sales order demand, and production order requirements.

This powerful out-of-the-box functionality suits the needs of most businesses. Still, we know that your business might require an integrated solution that provides industry-leading predictive algorithms. Thankfully, we can help you explore the vast ecosystem of integrated solutions such as Netstock and Eazy Stock while still maintaining a single source of truth.

Streamlined Purchasing

With an integrated ERP, you can manage and streamline your purchasing, receiving, and Accounts Payable within the same system to ensure a steady supply of materials while enforcing policy and process controls. Create purchase orders with approval rules for various order types, vendors, order amounts, and other order-specific information. With predefined approval structures built specifically for your unique needs, you can keep tight control over your entire procurement process.

If your business has a multi-company structure, modern systems like Acumatica will streamline your cross-company purchasing by automatically creating a sales order in one company from a purchase order in another company. Additionally, you might benefit from being able to generate drop shipment purchase orders from open sales orders automatically.

Once a shipment hits your dock, a new process begins: your team validates quantities and receives in the inventory. By managing your inventory in a system tightly integrated with your purchasing, you can ensure that your single data source is accurate and up-to-date, speeding up your order fulfillment and making your customers happy.

When you receive bills for landed costs, simply add them to the receipt so you can maintain a record of the true cost of goods, supporting your profitability analysis and informing sales prices. If your company receives a high level of overseas containers, we can explore additional Container Management functionality with you to provide enhanced visibility on your inbound inventory and allow you to easily allocate your landed costs to all POs within a container.

Inventory Control

We prefer to recommend systems that include a fully integrated Warehouse Management system, enabling you to manage your entire quote to cash workflow in one platform. If you are currently struggling to maintain visibility on your inventory levels, you will realize significant benefits with a system that provides warehouse location tracking and control. Knowing your inventory quantity and locations will never be a mystery!

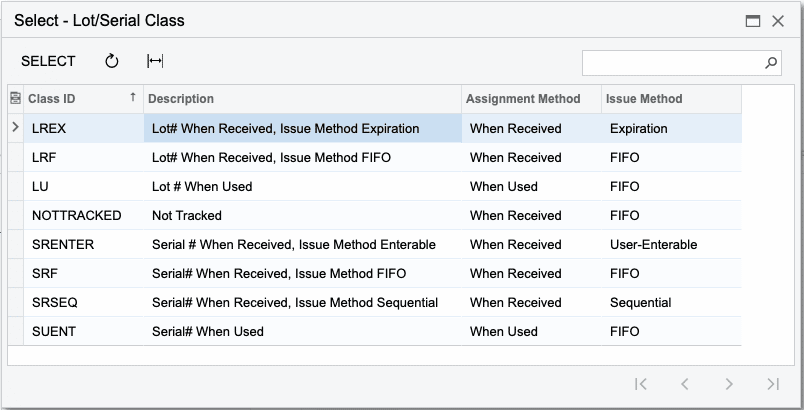

If you carry stock items that require lot or serial number tracking for your inventory items, we can help! With configurable options, you can decide if you will automate or manually assign numbers, track expiration dates, and specify your issue method. This level of tracking helps your warehouse team pick the correct items and also provides significant benefits if you encounter any recalls or quality control issues.

Order Fulfillment

While the traditional route for picking involves printed pick tickets, we know that a lot of organizations are intent on moving toward a paperless environment. We recommend that you consider platforms that support directed paperless picking capabilities, as it shortens the time per pick, allowing you to process orders faster with less staff. See below for our video on how you can empower your team with options for single-shipment, wave, and batch picking in a paperless environment.

If you are running a high-volume warehouse operation, your staff might be spending a lot of time generating tracking numbers and printing shipping labels from an outside system, such as FedEx Ship Manager or UPS Worldship. We can help you automate this process by providing native shipping carrier integration, keeping you in one system for the entire purchasing, warehousing, and shipping process.

Closing:

Our team at Opus Global Data Solutions specializes in implementing ERP software for those in the manufacturing and distribution industries. Our decades of experience have taught us that every business is different, so we work with you to identify your needs and develop customized solutions that address your key pain points.

Are you interested in learning more? Let us hear your ideas and vision to determine the next steps in your ERP evaluation. Please schedule a call with us or request a demo.