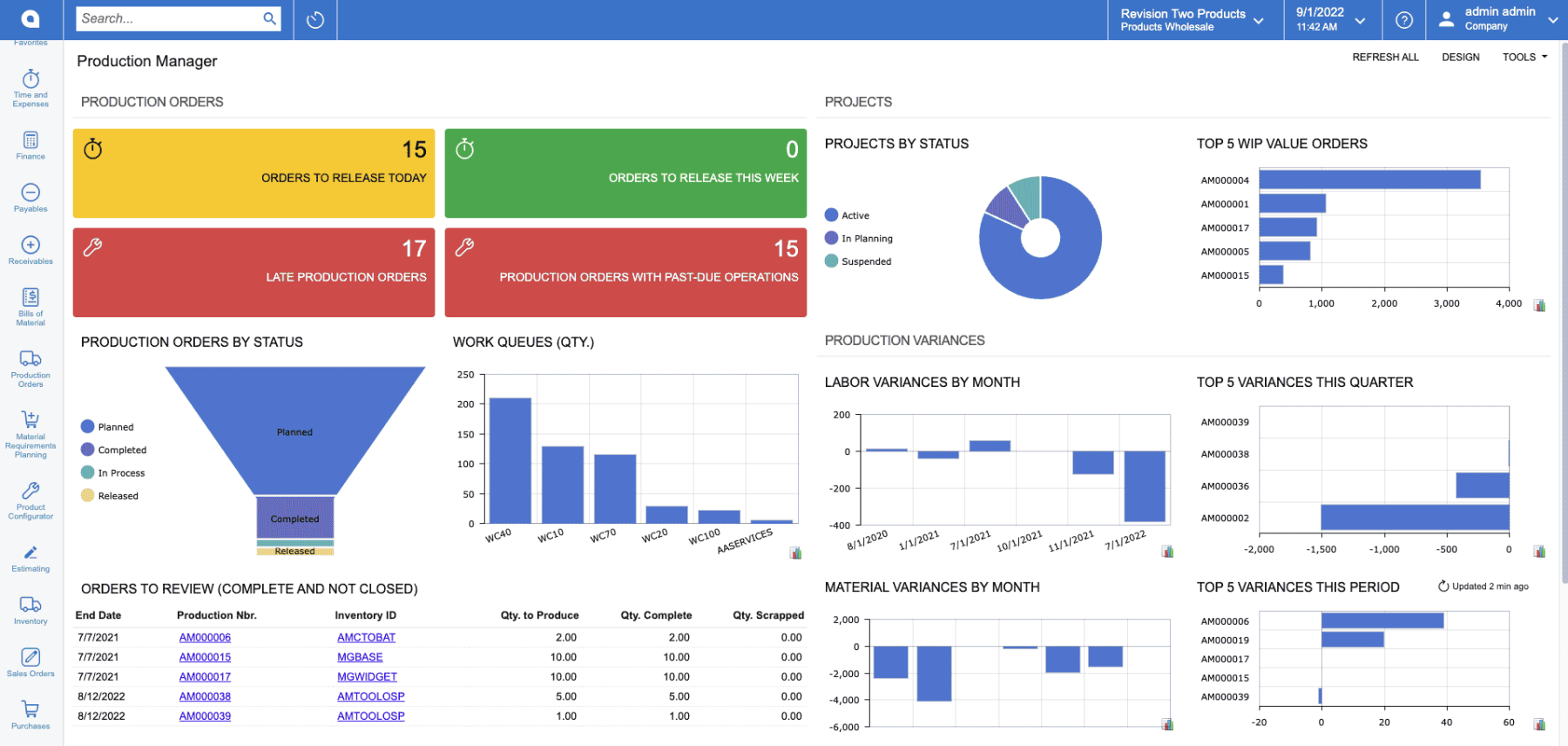

Our team at Opus Global Data Solutions understands that manufacturing managers and supervisors operate at their best when they have real-time views into crucial metrics such as production capacity, job costing and variances, and work order status, among others. However, these metrics are tough to provide if you are struggling on a legacy ERP, or are reliant on spreadsheets and disconnected systems.

In this blog, we will provide the key considerations for Production Managers and supervisors seeking to streamline their operations in a modern ERP platform. If you are a CEO, CFO, CRO, Warehouse Manager, or stakeholder in purchasing and operations, click here to see additional relevant content.

Engineering

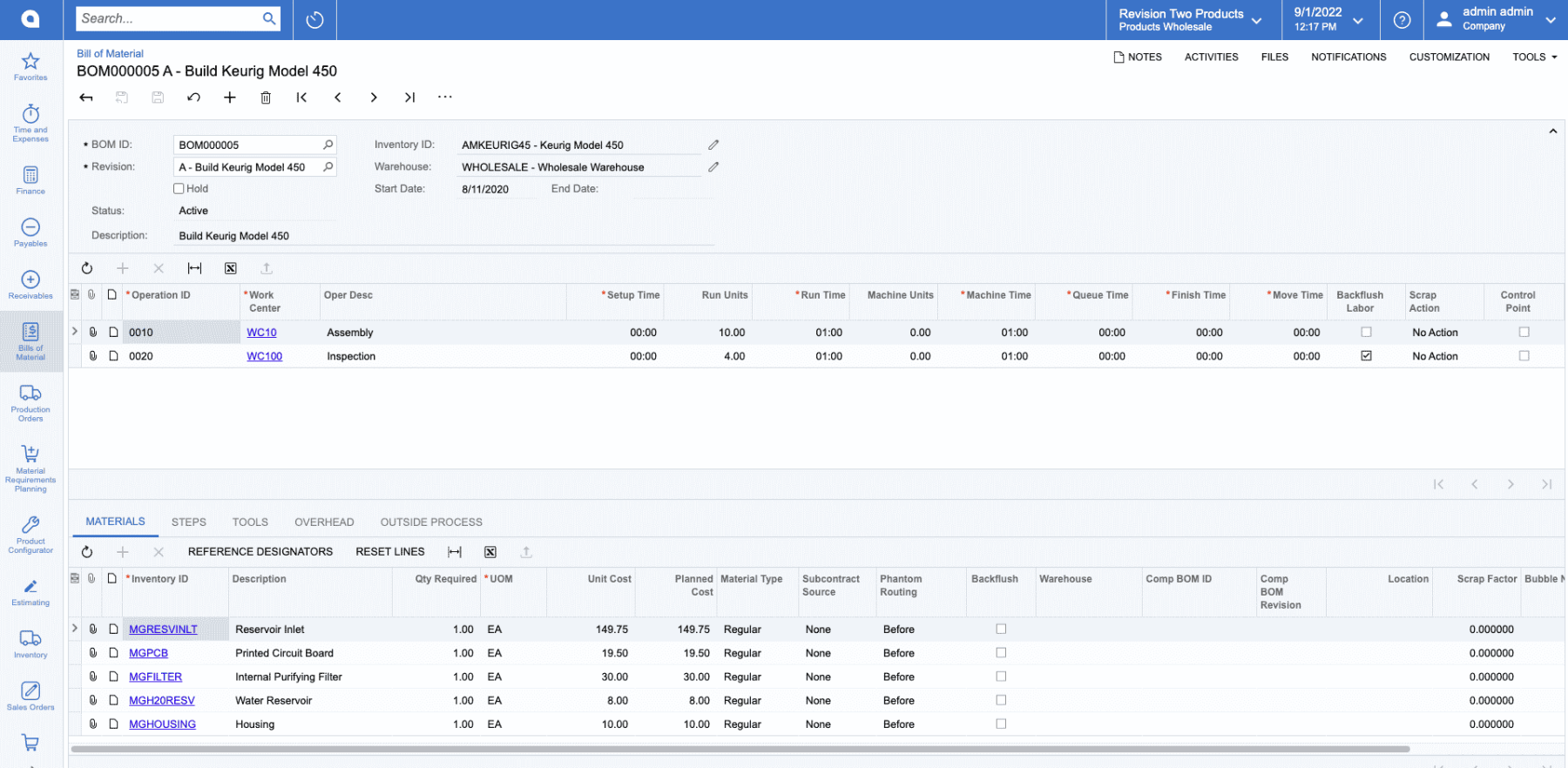

It all starts with the BOM! If you can’t build a dynamic multi-level bill of material within the systems you are evaluating, it’s time to search elsewhere. On the example BOM below you will see multiple operations with specified labor and materials.

If you are currently using a vendor for an outside process, you can manage that right within the same system by defining a work center as a vendor and creating and receiving purchase orders right from your production order.

Are your engineers using CAD software to design your products? We can help you with data import, or even better, streamlined integration between your CAD system and ERP. Reach out to learn more.

Purchasing and Production Suggestions

We know that each manufacturer is different. The items you carry might be make-to-stock, make-to-order, configure-to-order, or maybe even a combination of all three. Regardless of your operations, it is crucial that you know when to buy materials and when to create production orders.

Our suggestion is to consider platforms that offer fully-integrated, robust Materials Requirement Planning (MRP) systems that provide a one-stop-shop for your supply plan. A good MRP system will identify all your sources of demand (production, min/max and safety stock, sales orders, forecasts) and provide action dates based on vendor lead times and manufacturing lead times.

Identifying replenishment needs is just one part of the process. Streamlined workflows should enable your purchasing and manufacturing managers to easily generate orders from your MRP view. See below for our video on MRP to learn more.

Scheduling

Production scheduling needs can vary just as much as the actual operations. You might be able to seamlessly run your production floor scheduling with pencil and paper or a spreadsheet, or you may need advanced software functionality to stay on target. If your business growth and complexity is forcing you to outgrow your current scheduling process, our team at Opus can help you evaluate several options and implement the correct solution that will address your specific needs.

A fully-embedded visual scheduling tool provides maximum visibility on order status, work center capacity, and productivity, enabling you to set realistic deadlines so your customers stay happy. See our video below for an example of a scheduling tool that some of our customers are using to stay on track!

Do your needs for finite capacity scheduling seem to go beyond these capabilities? Our experts can work with you to evaluate and implement an integrated solution that will address your major pain points. Please reach out so we can begin that conversation!

Labor + Material Transactions

Our solutions provide options for adding the appropriate costs to your jobs, either through barcode scanning, a mobile data collection application, or on your web browser.

1. Backflush: Stick with the default materials and labor on the BOM, which can include setup time, machine time, and different labor rates depending on the operation. Materials and labor will post to the job as you move to the next operation.

2. Direct Material Issue: Issue all materials at the beginning of a job, or do so at the end of each operation. Your WIP and Inventory accounts will stay up to date!

3. Direct Labor Issue: Depending on your needs and goals, this might happen throughout the day, or at the end of the week as your employees (or a supervisor) input the labor for each production order and operation they completed.

4. Clock Entry: Your employees clock in and out of production order operations, providing the most accurate labor time for your costing. We know there is always a concern that an employee might forget to clock out, but we have that covered with dynamic approval maps that require approval from a supervisor before the labor is issued to the work order.

We can’t tell you which method is best until we meet you, but we can say without a doubt that having multiple options provides you the ability to grow within your system.

Reporting

We know that obtaining a more accurate view of job cost is one of the main drivers for manufacturers who are exploring new software systems. If sales orders, purchasing, and manufacturing are managed in the same system, you will be able to identify the true costs of production to support an accurate profitability analysis. Between the options available for material and labor issues, as well as the capability to configure and assign overhead costs to specific operations or work centers, there is no limit to generating the reporting necessary for informed decision-making.

Closing:

Our team at Opus Global Data Solutions specializes in implementing ERP software for manufacturers, and our decades of experience have taught us that every business is different. If you would like us to work with you to develop customized solutions that address your key pain points, please schedule a call with us.