This is the final blog post in our series on digitally transforming your business with Acumatica, the Cloud ERP. Previously, we covered Manufacturing with a Modern ERP. In this post, we will explore how you can use a robust, modern platform to manage and streamline your equipment manufacturing business.

There are many complex business challenges during and after production for equipment manufacturers. Operations managers must be able to balance resource availability and customer needs in a cost-effective manner. To schedule service for the equipment, customer support staff need to be able to access accurate records for warranties and service history. Service Technicians also need to have confidence that the customer and equipment information provided by the back office is reliable to deliver quality customer service in a timely fashion.

Our team at Opus can help you meet all these needs with advanced manufacturing and service management functionality. With Advanced Planning and Scheduling, your operations managers will have greater visibility and insight into key metrics to optimize on-time deliveries while reducing inventory levels and waste. Additionally, your service team will be able to increase profitability and efficiency by effortlessly tracking equipment and service history post-sale.

Production Schedules

Does it take you hours to schedule your production manually? With Advanced Planning and Scheduling (APS), that process can now take seconds. APS is found within the Acumatica Manufacturing Edition and is used solely for finite scheduling. Finite scheduling is a more precise method of scheduling that considers the available capacity of a facility’s resources and allows you to increase your operational efficiency without overloading machines or work centers. The system will confirm the production schedule is realistic so your production orders and fulfillment times are met.

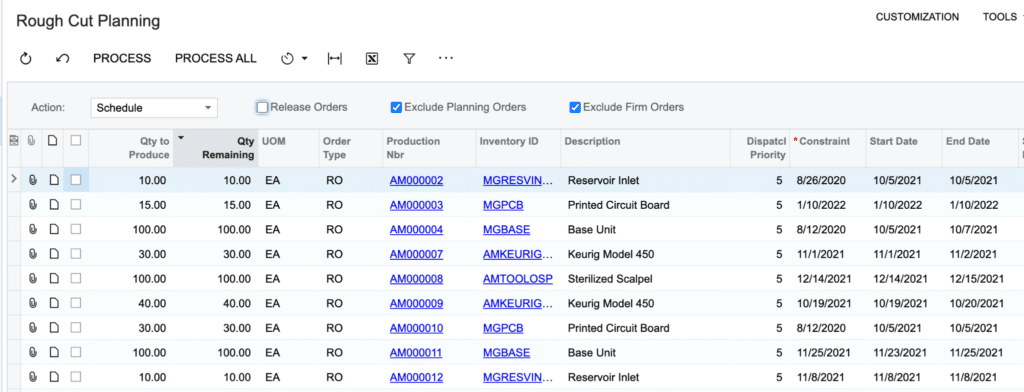

Rough Cut Planning is one of the most important steps of production scheduling. It verifies that you have sufficient capacity to meet the requirements for your master schedule. The Rough Cut Planning Screen in Acumatica displays all pertinent information related to the order in a generic inquiry report. This allows the user to filter for specific orders they want to review, plan, and schedule. Users have visibility into all orders through the Rough Cut Planning Screen and Production Schedule Board.

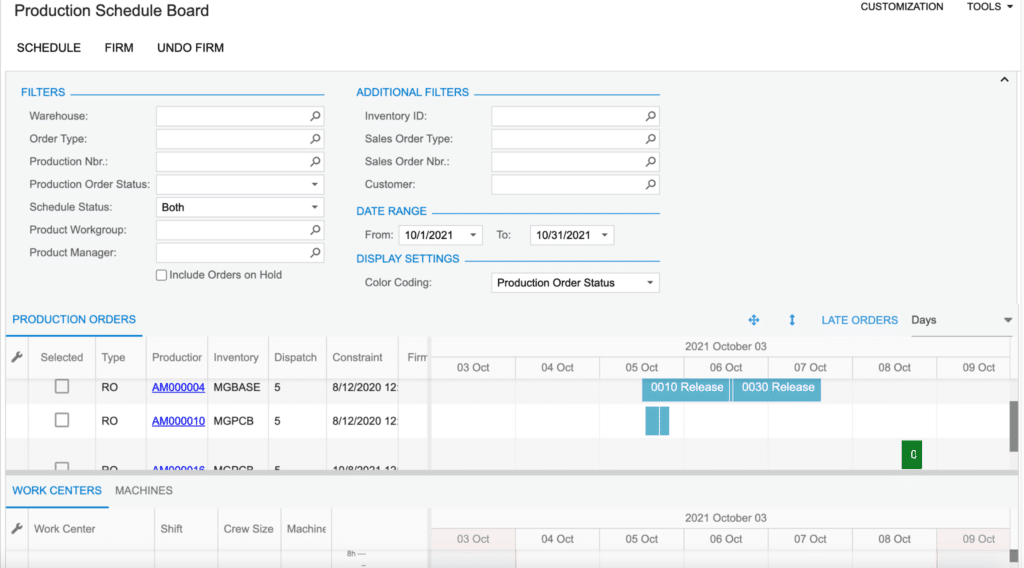

The Production Schedule Board allows users to visualize the production order in a Gantt chart. Visual scheduling offers your team the flexibility to view production schedules by production order, or for all orders simultaneously thus optimizing the production process.

Equipment Tracking

For many manufacturers that service equipment post-sale, a spreadsheet is often the only way to track service events and history. Acumatica’s Field Services Module allows users to automate and track equipment after production, shipping, and invoicing; ultimately leading to increased customer service and satisfaction.

Resource and Target Equipment are the two major categories within Acumatica’s Equipment Management module. Target Equipment is the customer’s item that you are servicing. For example, this could be an air conditioner that was installed during a previous service appointment. This module also provides visibility into Resource Equipment, which are the items that are used by technicians during service appointments, such as a power drill for an installation job. This functionality gives your field service technicians every detail about the equipment which translates to faster and more reliable customer support. Acumatica truly brings all your teams together, from production to shipping, all the way through service and accounting.

Warranty Management

Equipment warranties are a great way to drive revenue and build consumer trust. However, if your ERP software is incapable of tracking warranties, you are left with manual tracking, which consumes valuable man-hours and is prone to human error. If the Target Equipment items your team services have a warranty or include component parts with warranties, that information can be easily tracked for both company and vendor warranties within the stock item record, allowing you to provide improved customer service by avoiding any improper billing.

Due to ease of customization, users can build personalized reports to help manage equipment warranties. With generic inquiry reports and filtering, users have visibility into all their soon-to-be “expiring” customer and/or vendor warranties in one central location. Business events can automatically notify a customer when a warranty is set to expire. The notifications can be sent out as an email, SMS text, or push notification. This also allows your customer support team to be proactive with their engagements with clients. By automating these tasks, your staff will have more time to focus on other revenue-generating responsibilities rather than manually tracking equipment warranties and emailing customer notifications. This ultimately leads to better customer service and increased efficiency.

Closing:

Are you interested in learning more? Let us hear your ideas and vision so we can help you determine the next steps in your ERP evaluation. Please schedule a no-obligation call with us or request a demo.